Ever wondered how a tree in the forest ends up as the paper you use to take notes or doodle during boring classes? The journey of wood to paper is pretty awesome – it’s like a science experiment, a factory adventure, and a bit of magic all rolled into one. Let’s break it down!

Step 1: Trees Become Logs

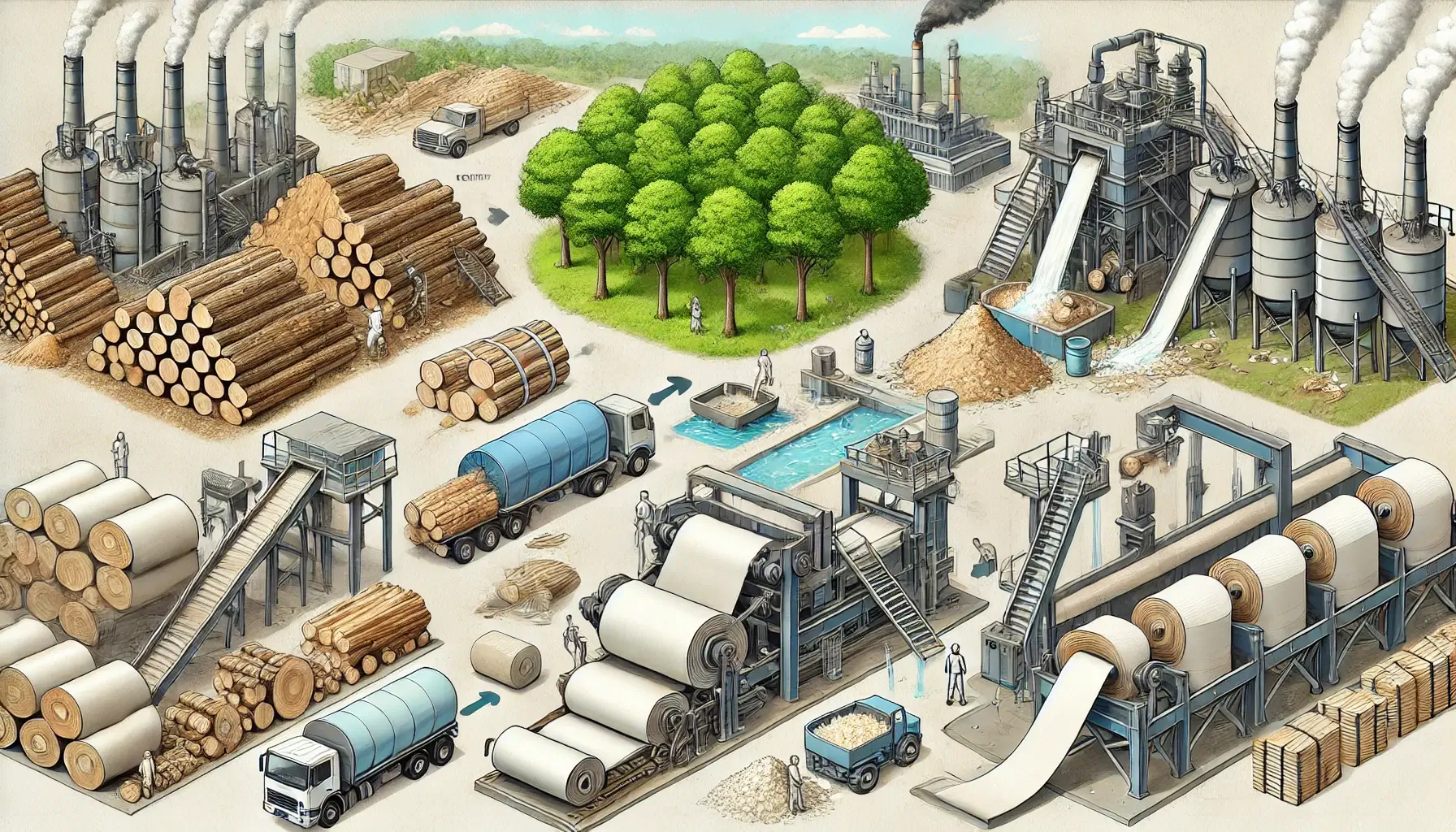

It all starts in a forest. Trees like pine, spruce, or eucalyptus are grown and carefully selected to become paper. Once ready, they’re cut down and transported to a mill. This is where they’re stripped of their bark and cut into smaller logs. Imagine a giant vegetable peeler, but for trees—that’s what happens to get rid of the bark.

Step 2: Turning Logs Into Pulp

Next, these logs are chopped into even smaller pieces, almost like turning the tree into wood chips. These wood chips then go into a “pulping” machine. This machine either boils the chips in chemicals or grinds them up with water until they break down into tiny fibers. This mixture of fibers and water is called pulp. It basically looks like a chunky, wet oatmeal at this point—not too tasty, but essential for making paper!

Step 3: Making the Pulp Smooth

Now, this pulp needs to be cleaned and smoothed out. It goes through several machines to remove impurities and clumps. Sometimes, bleach is added to make the pulp whiter, which makes the paper easier to write on. You can think of this step like when you wash your laundry—the pulp is getting cleaned up to look fresh.

Step 4: From Pulp to Paper Sheets

Here’s where it gets really cool. The cleaned pulp is spread out on a massive flat screen that drains out the water. The pulp fibers begin to stick together, forming a thin mat. Picture spreading a thin layer of mashed potatoes on a screen and letting it dry—only way more watery and smooth. Rollers then press the mat to squeeze out even more water, making it flat and solid.

Step 5: Drying and Finishing Touches

The almost-paper is then sent through huge heated rollers to dry completely. This is where it finally starts looking like the paper you know. After drying, it’s smoothed out and sometimes even coated to make it glossy or easier to write on. If it’s going to be printer paper, it might get cut into those perfect rectangular sheets you see in reams at school.

Step 6: Ready for Use!

Finally, the paper is rolled into massive rolls or cut into sheets, ready to become notebooks, textbooks, or even toilet paper. It’s pretty wild to think that the same stuff that once formed a giant tree is now sitting in your backpack, ready for your next masterpiece—whether it’s a sketch, an essay, or just a doodle of your favorite band logo.

The Bigger Picture

The whole process might sound simple, but there’s a lot of technology, science, and even some environmental responsibility involved. Sustainable paper companies plant new trees to replace the ones they use, making sure forests keep growing. So next time you grab a sheet of paper, remember that it started out as part of a towering tree, survived some intense chopping, boiling, and pressing, all so you could write that math homework (or maybe just a funny note to a friend).