Wood is one of the most widely used sources of fibre for paper and pulp production. As a natural, renewable resource, wood plays an essential role in the paper industry, providing the raw materials needed to manufacture everything from newsprint and cardboard to fine writing paper. The process of converting wood into pulp is fundamental to the modern paper industry, which relies on this fibre source to meet the growing global demand for paper products.

Types of Wood Used in Paper Production

Two primary types of wood are used in pulp and paper production: softwood and hardwood. Softwood, sourced from trees like pine, spruce, and fir, is known for its long fibres, which provide strength and durability to the paper. Hardwood, derived from trees such as birch, poplar, and eucalyptus, has shorter fibres, which contribute to a smoother and more opaque final product. Often, a combination of both types of wood is used to achieve the desired balance of strength, smoothness, and printability.

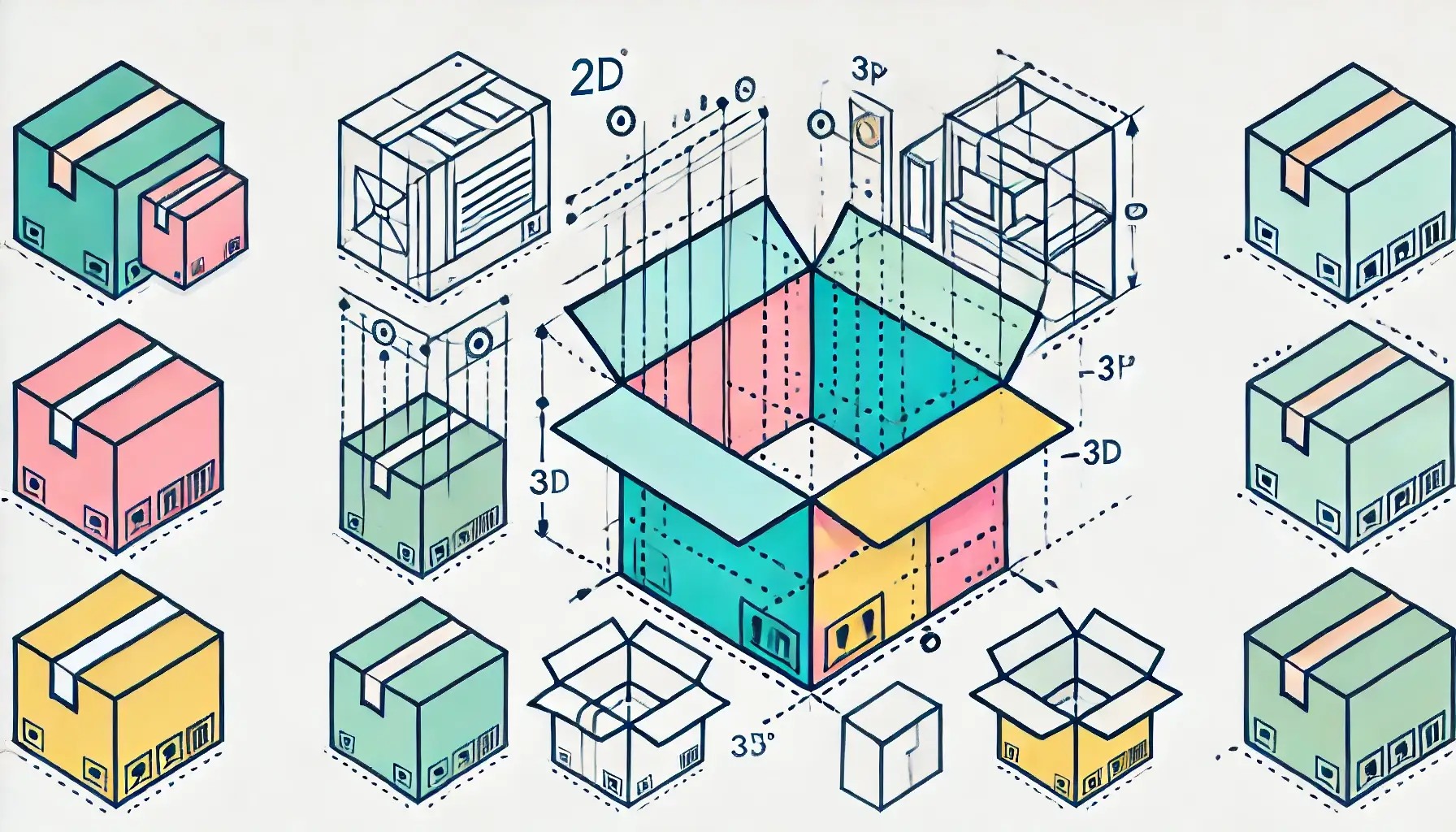

Pulping Methods

The process of extracting fibres from wood is known as pulping. There are several methods of pulping, including mechanical, chemical, and semi-chemical. In mechanical pulping, wood is ground down to separate the fibres, resulting in a pulp that retains most of the wood’s original lignin content. This type of pulp is often used for lower-grade papers, like newsprint. Chemical pulping, on the other hand, uses chemicals to dissolve lignin and separate the fibres, resulting in a higher-quality pulp suitable for stronger, more durable paper products. Kraft and sulfite are the most common chemical pulping processes.

Advantages of Using Wood as a Fibre Source

1. Renewable Resource: Wood is a renewable resource, making it an environmentally viable option for paper production. With responsible forestry practices, trees can be regrown to ensure a continuous supply.

2. High Fibre Quality: Wood provides high-quality fibres that are essential for producing a wide range of paper products, from tissue to packaging materials.

3. Versatility: The combination of hardwood and softwood allows manufacturers to create paper with a variety of properties, including strength, softness, and smoothness, depending on the end-use requirements.

Environmental Considerations

While wood is a renewable resource, its use in paper production must be managed responsibly to avoid deforestation and environmental degradation. Sustainable forestry practices, such as replanting trees and reducing waste, are crucial to ensuring that wood remains a viable source of fibre for the long term. Additionally, many paper manufacturers have adopted certifications like the Forest Stewardship Council (FSC) to ensure that their wood sources are sustainably managed.

Conclusion

Wood remains an indispensable source of fibre for the paper and pulp industry, providing the raw materials needed to produce a wide variety of paper products. By using a combination of softwood and hardwood, along with employing sustainable forestry practices, the industry can continue to meet the global demand for paper while minimizing its environmental impact. The use of wood as a fibre source highlights the balance between economic needs and environmental stewardship that is essential for the future of paper production.