Introduction

Hey there, curious minds! 🌟 Have you ever held a newspaper and wondered, “What kind of paper is this?” It’s not quite like the paper in your notebooks or the glossy pages of a magazine. This special paper is called Newsprint Paper! Today, we’re going to explore what newsprint paper is, how it’s made, how it’s different from other papers, and all the cool ways it’s used. Ready for an adventure? Let’s go! 🚀

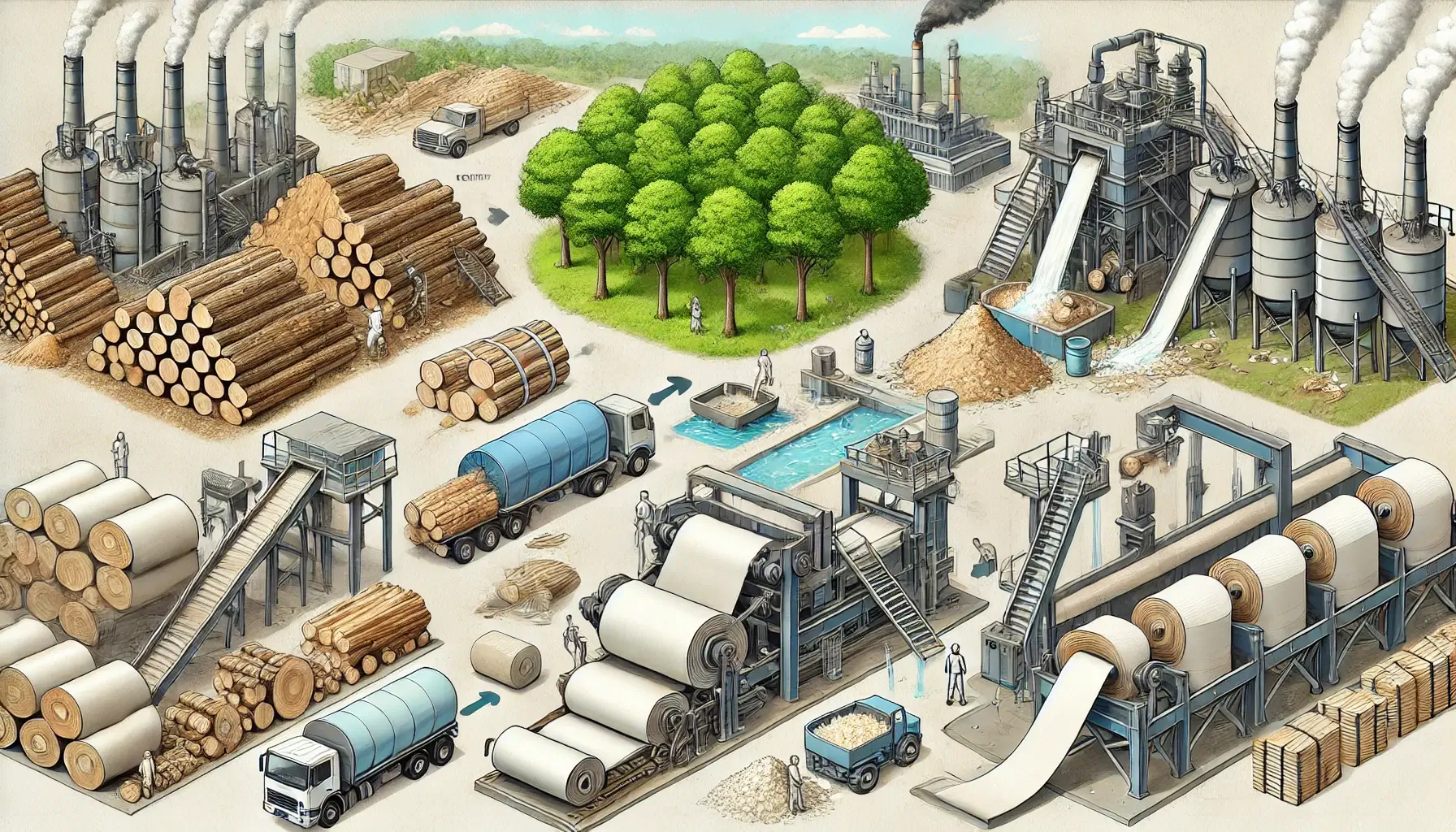

What is Newsprint Paper?

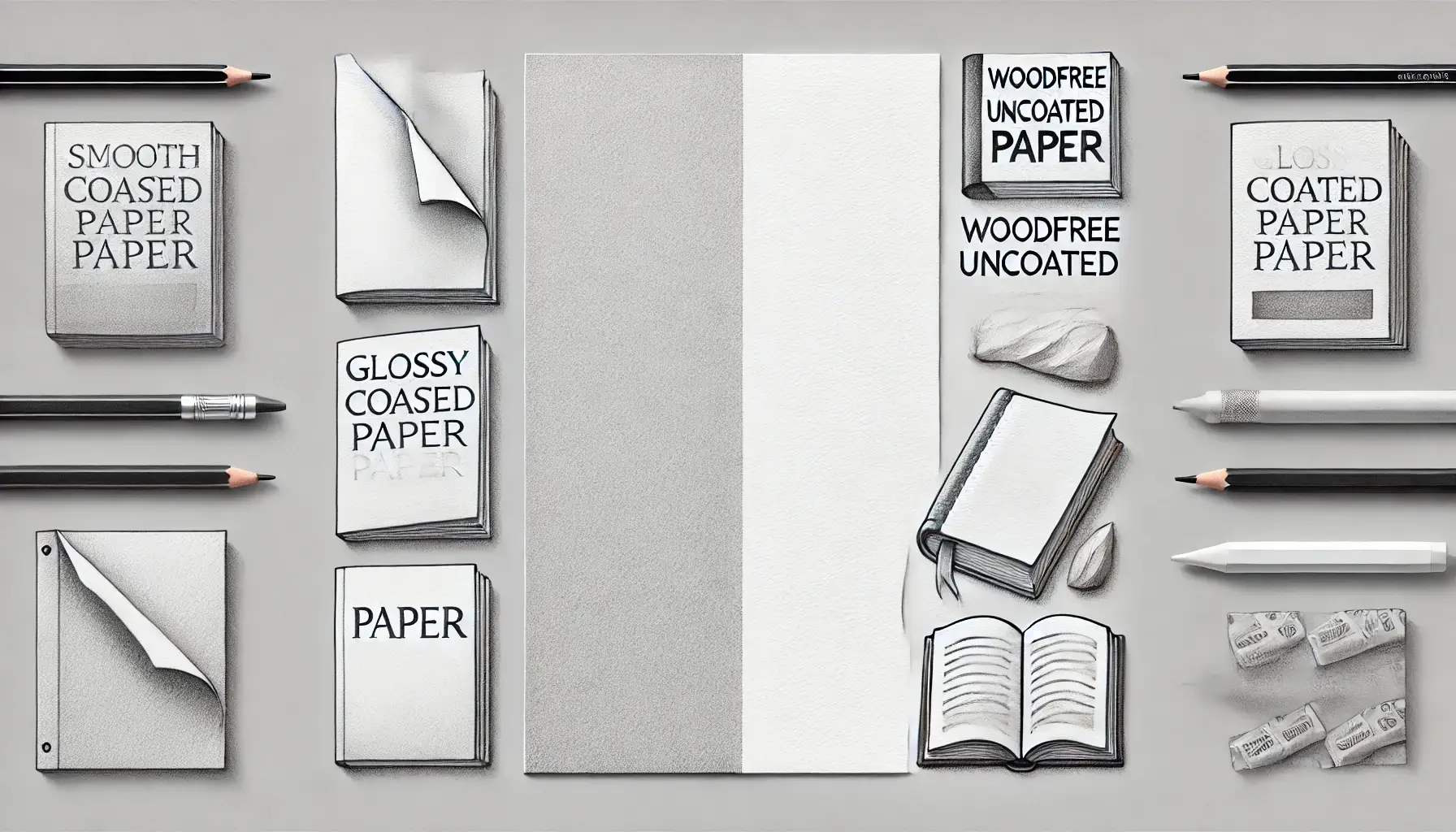

Newsprint Paper is a type of paper that’s lightweight, inexpensive, and perfect for printing newspapers, comics, and more. It’s known for its slightly rough texture and off-white color. Because it’s easy to produce in large quantities, it’s the go-to paper for printing news that reaches millions of people every day!

How is Newsprint Paper Different from Other Papers?

- Cost-Effective 💰: Newsprint is cheaper to make because it uses less processing and fewer chemicals.

- Color 🌈: It has a natural, slightly gray or off-white color, unlike the bright white of printer paper.

- Texture 👐: It’s thinner and has a rougher feel compared to smoother, thicker papers.

- Durability 🛡️: Newsprint isn’t as durable; it can tear more easily and may turn yellow over time.

- Ink Absorption 🖋️: It absorbs ink quickly, which is great for fast printing but can cause smudging if touched too soon.

Cool Uses of Newsprint Paper

1. Newspapers and Comics 🗞️

The most common use! It allows for quick and mass production of daily news and fun comics.

2. Art and Crafts 🎨

Artists use newsprint for sketching and practicing because it’s affordable and great for charcoal or pencil drawings.

3. Packaging Material 📦

It’s used to wrap fragile items or fill empty spaces in packages to protect items during shipping.

4. Classroom Fun 🏫

Teachers use it for big art projects, murals, and covering bulletin boards.

5. DIY Projects ✂️

From paper mâché to homemade kites, newsprint is perfect for creative projects.

Fun Activity: Create Your Own Newspaper! 📰

Materials Needed:

- A few sheets of newsprint paper (or any large paper you have)

- Markers, crayons, or colored pencils

- Imagination!

Steps:

- Name Your Newspaper: Come up with a catchy name like “The Daily Adventure” or “Kids’ News Now”.

- Write a Headline: Think of an exciting event—maybe a school achievement, a sports victory, or a fictional story.

- Compose an Article: Write a short story about your headline. Remember to include the who, what, when, where, and why!

- Add Pictures: Draw illustrations or even paste photos (with permission) to make it look real.

- Share It: Show your newspaper to family and friends or display it in your room!

Did You Know? 🤔

- Fast Production: Newsprint allows newspapers to be printed at incredible speeds—some machines can print over 60,000 copies per hour!

- Recycling Champion: Newsprint is highly recyclable, which helps save trees and reduce waste.

- Historical Importance: Newspapers have been around for centuries, spreading important news to people all over the world.

Quiz Time! 📝

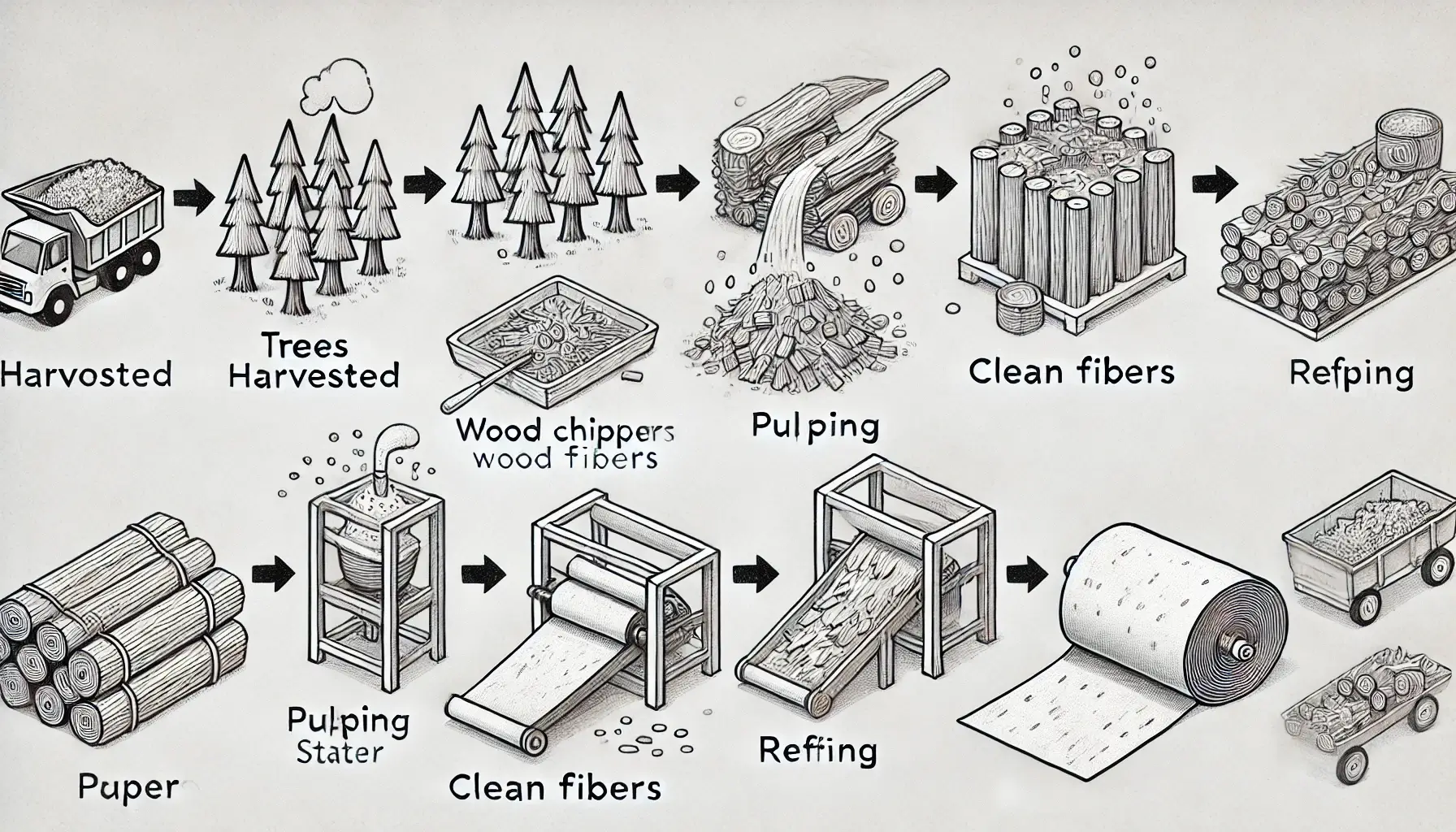

- What process is mainly used to make newsprint paper? A) Chemical pulping B) Mechanical pulping C) Digital printing

- Why is newsprint paper cheaper than other papers? A) It’s made from plastic B) It uses less processing and fewer chemicals C) It’s imported from space

- What is a common use for newsprint paper besides newspapers? A) Building houses B) Art and crafts projects C) Making smartphones

Answers: 1-B, 2-B, 3-B