India, one of the fastest-growing economies in the world, has seen a significant surge in its demand for pulp over the past decade. As the country expands its industrial base and consumption of paper products increases, the pulp and paper industry has become a critical component of its economic growth. Here’s an overview of the factors driving pulp demand in India and what the future holds.

Factors Driving Pulp Demand

- Rising Population and Urbanization

India’s population, the second largest in the world, continues to grow rapidly, driving the demand for paper and packaging products. As urbanization accelerates, the consumption of paper for packaging, printing, and writing has increased. This, in turn, has fueled the demand for pulp as a primary raw material.

- E-commerce Boom

The rise of e-commerce has drastically reshaped the packaging landscape in India. With more consumers shopping online, the need for corrugated packaging, kraft paper, and other pulp-based packaging materials has skyrocketed. Online retailers require durable and eco-friendly packaging solutions, boosting the demand for high-quality pulp.

- Increased Focus on Education

India’s emphasis on education, coupled with government initiatives promoting literacy and education access, has led to greater demand for paper used in textbooks, notebooks, and other educational materials. This ongoing trend increases the consumption of pulp to meet the needs of the expanding education sector.

- Shift Towards Sustainable Packaging

As environmental awareness grows, India is moving toward sustainable and eco-friendly packaging solutions. Many businesses are shifting away from plastic packaging to pulp-based alternatives like paper bags, cartons, and biodegradable packaging. This shift has significantly increased the demand for pulp as manufacturers look for sustainable packaging solutions.

- Growth in the Consumer Goods Sector

The fast-moving consumer goods (FMCG) industry in India is also a major contributor to the rise in pulp demand. With the growing consumption of packaged goods, beverages, and personal care products, the need for pulp-based packaging and labeling materials has soared.

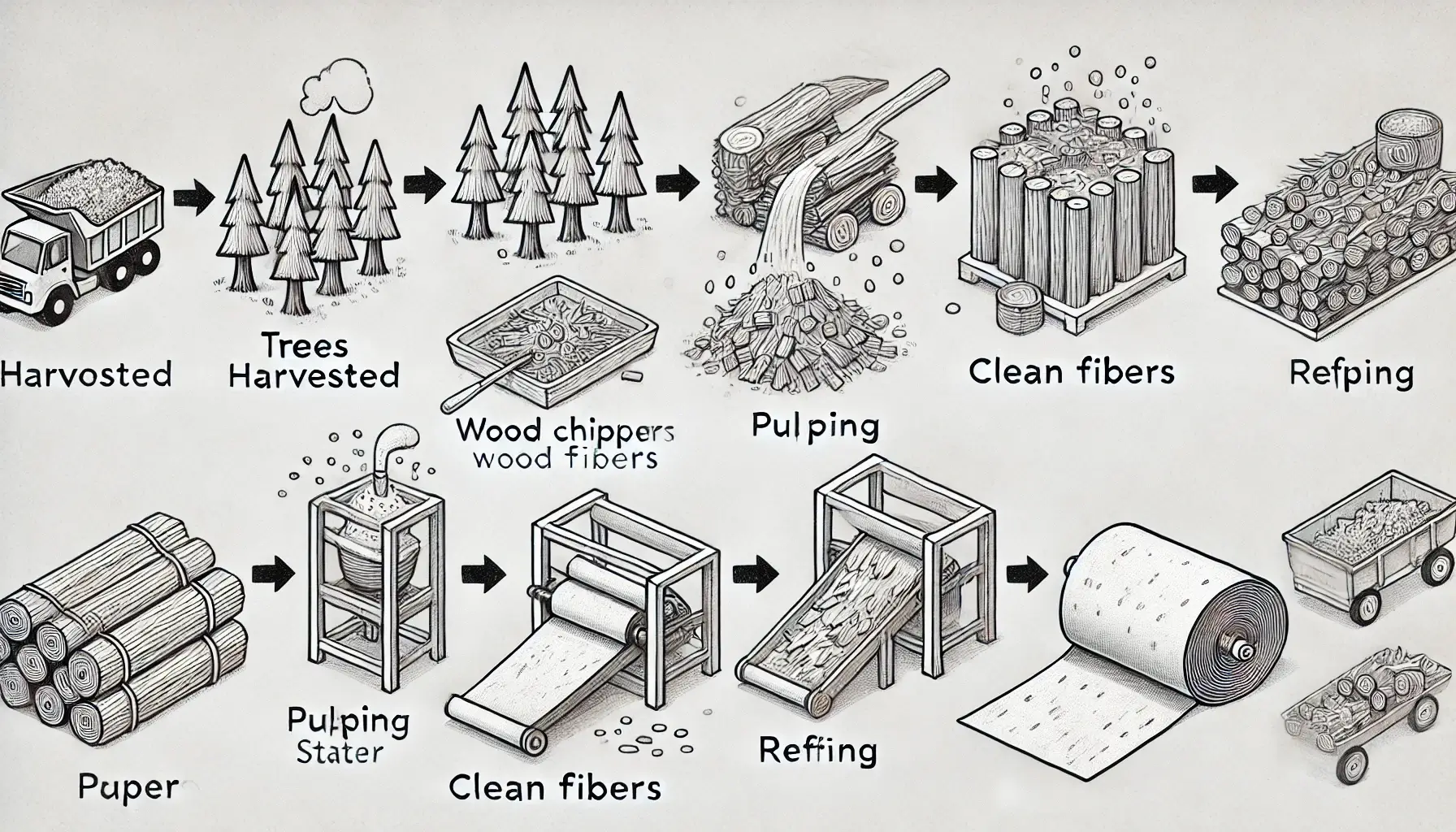

Domestic Pulp Production vs. Imports

India’s domestic pulp production is not sufficient to meet the growing demand, leading to a significant reliance on imports. The country imports both wood pulp and recycled pulp to support its paper and packaging industries. Countries like Indonesia, Canada, and the United States are among the major suppliers of pulp to India.

This dependency on imports presents both challenges and opportunities. On the one hand, Indian paper producers are exploring ways to increase domestic pulp production through sustainable forestry and agro-based pulp. On the other hand, global suppliers see India as a lucrative market for pulp exports.

Challenges Facing the Pulp Industry in India

- Raw Material Availability: India faces challenges in sourcing raw materials for pulp production. The country’s limited forest resources and regulations around deforestation restrict large-scale domestic production. As a result, there is a growing focus on alternative raw materials, such as agricultural residues and recycled paper.

- Sustainability Concerns: As the demand for pulp grows, the need for sustainable sourcing becomes increasingly important. The Indian government and private sector are emphasizing responsible forest management and the use of certified sustainable pulp to minimize environmental impact.

- High Costs of Importing Pulp: The reliance on imported pulp exposes Indian manufacturers to fluctuations in global pulp prices and currency exchange rates, which can impact production costs. This challenge has driven the industry to explore cost-effective alternatives, such as local sourcing and recycled pulp.

Future Outlook

The demand for pulp in India is expected to continue growing in the coming years, driven by the e-commerce boom, rising packaging needs, and the shift towards eco-friendly solutions. The Indian government’s focus on expanding education and infrastructure development will also play a key role in shaping the industry’s future.

To meet this demand, there will likely be an increase in investment in domestic pulp production, sustainable forestry practices, and the development of innovative packaging solutions. At the same time, India’s reliance on imported pulp is expected to continue, presenting opportunities for global pulp producers to cater to this expanding market.

Conclusion

India’s growing demand for pulp is being driven by urbanization, e-commerce, education, and sustainability initiatives. While challenges like raw material availability and dependence on imports remain, the country’s expanding economy and increasing environmental awareness create a fertile ground for growth and innovation in the pulp and paper industry. With strategic investments and a focus on sustainability, India is well-positioned to meet its rising pulp demand while contributing to a greener future.